Barcode Inspection

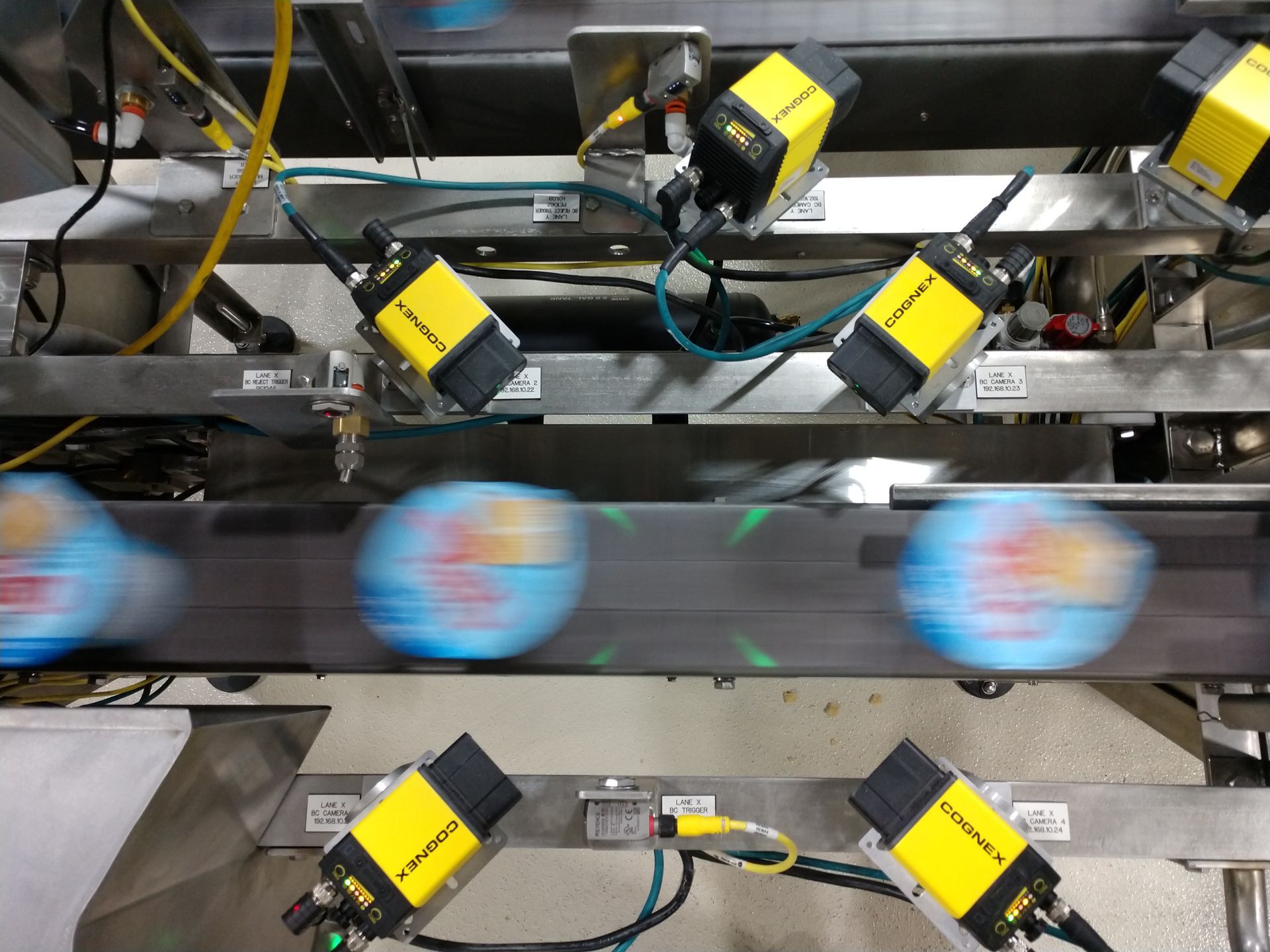

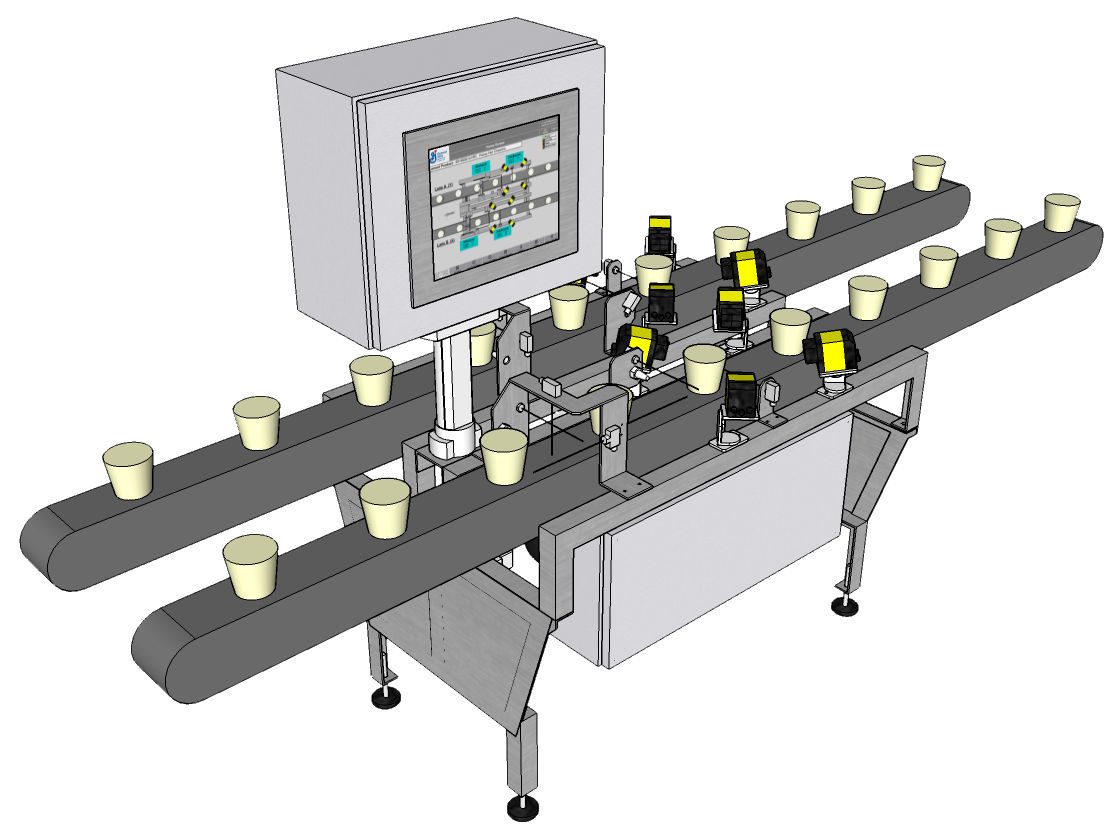

600 Cups/Min Barcode Inspection & Rejection

Challenge

The customer requested a system that would inspect cup 1D barcodes on a two-lane conveyor system at a rate of 300 cups/min on each lane. The conveyor line speed was specified to be more than 200 ft/min. A 4-reader synchronized system was designed to provide 360-degree coverage around each cup. With a 65ms window to capture 4 images, transfer results, and validate the transferred results, proper lighting and tuning of image acquisition was critical. Extensive in-house testing was necessary to validate the system's performance prior to on-site commissioning.

Value

High speed production equipment is more and more necessary to meet high consumer demands. Inspection and validation of the product on the line is increasingly necessary as well. However, the inspection equipment should not hinder the production rates of the production equipment. CDSL is committed to creating a custom solution to meet the needs of the customer. Our custom solutions utilize COTS hardware whenever possible to help minimize downtime where proprietary configurations and long lead hardware can otherwise cause unnecessary delays.