Experience

Grain Handling System

Minimize operator intervention.

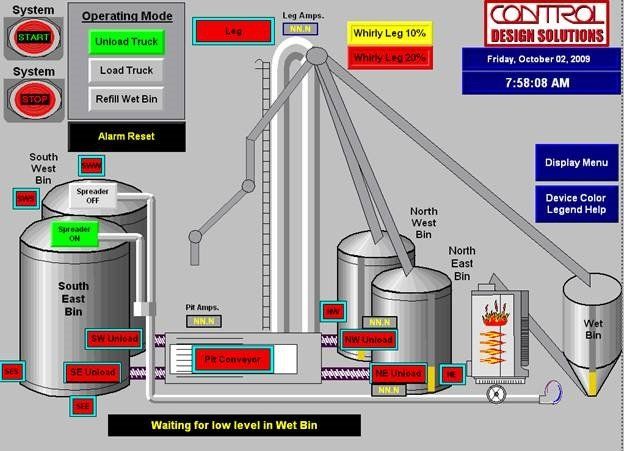

To integrate control of all associated equipment into a central control system with a color graphic user interface for easy-to-understand control from a central location, thus; reducing operator intervention while increasing efficiency.

Challenge

CDSL integrated a programmable logic controller and a pc-based HMI to automate the grain handling process. Among other things this gives the system operator the ability to initiate transfer sequences with a single button. The system automatically performs a sequential shutdown, clearing the system, once the transfer is complete. The automatic control provides interlocks with downstream equipment and reduces energy consumption by shutting down idle equipment. Automatic control includes operator adjustable run duration and run intervals settings for the bin aeration fans. Manual control for all motors is provided via the HMI. System alarm displays, motor current draw displays and trend are also provided as operational and trouble-shooting aides. Controls include over-current and no-load shutdown. The PC utilized for the HMI provided the means to incorporate a data base application which tracks production by commodity, by farm, by variety and by owner. The application provided data entries for all loads including, farm identification, weights, moisture, test weights, foreign material, and sell/store/contract designation. Additionally, the application tracks the status of grain contracts.

Value

Integration of the grain handling system equipment allows the system to continuously monitor and automatically control all associated equipment based on any change within the system. The system is easier to use than a hardwired system. It maximizes throughput while protecting and extending the life of equipment. This automation provides improved control, greater flexibility, and ease of operation with less intervention which ultimately allows the owner to be more productive.