Experience

New Blanking Line

Installation of Used Equipment

CDSL has extensive experience in evaluating and upgrading used capital equipment. Our knowledge and experience aid customers that need to put capital equipment back in to service in a way that is efficient and cost effective.

Challenge

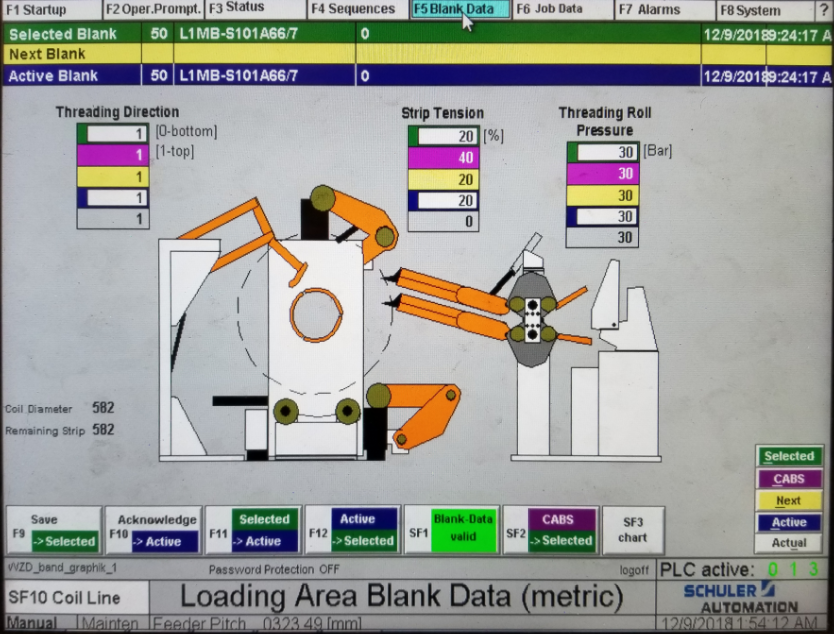

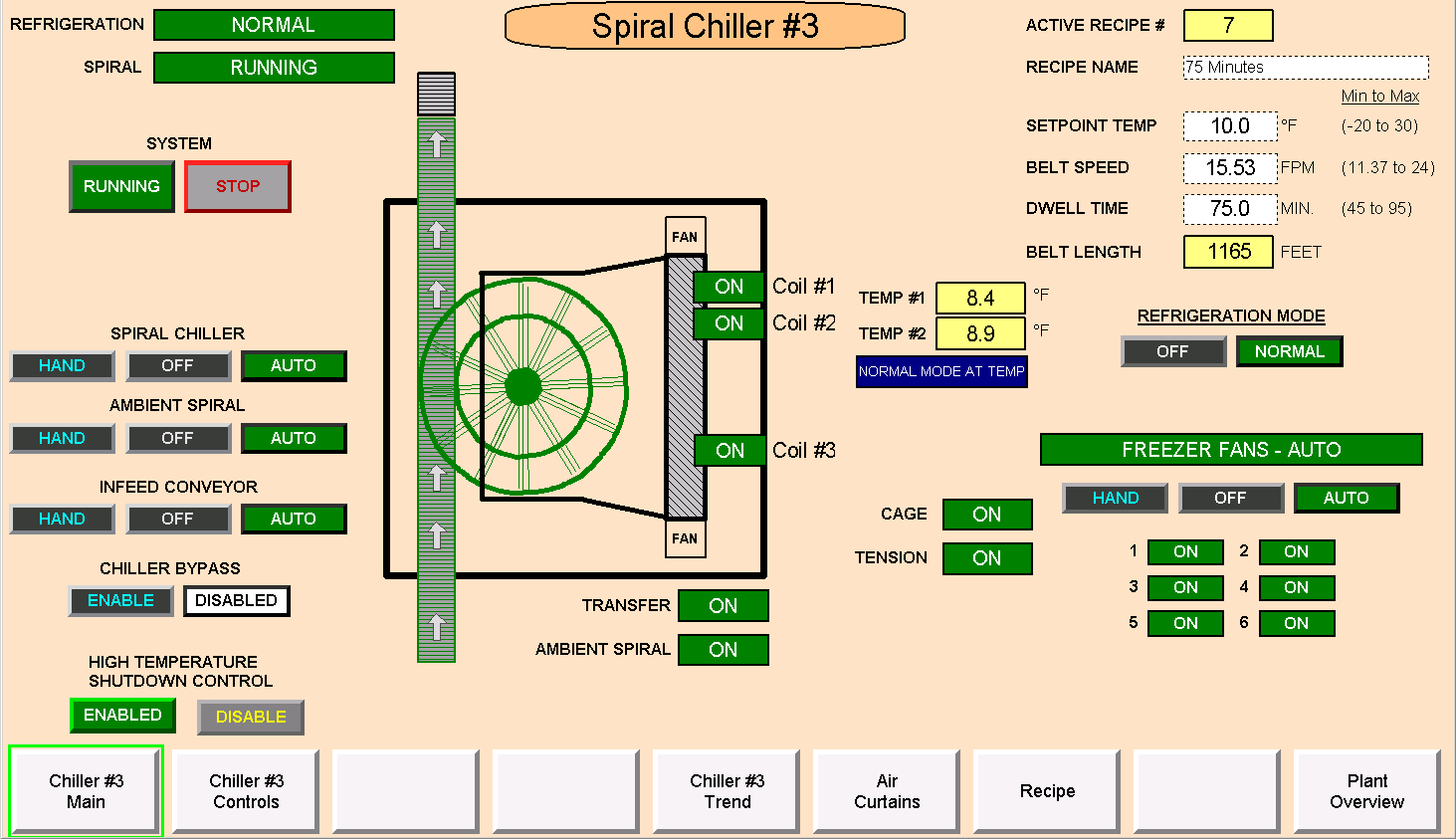

Our customer had purchased the capital equipment necessary for a steel line from a variety of used equipment sales. We were tasked with evaluating each piece of equipment to see what controls were already there and determine if the existing controls could be salvaged in their entirety or in part. We would also need to determine what other controls would be necessary to make the different pieces come together as a cohesive and efficient steel production line. Once this was completed, we were responsible for providing the design package, installation package and any necessary hardware necessary for the project. We decided to move forward with a new central controller that would be large enough to accommodate controlling every piece of equipment on the new line. We made this decision as most of the supplied controls were made up of obsolete controllers and hand wired systems. New remote Ethernet I/O racks were installed local to each piece of equipment to minimize wiring. During our investigation we found that the large (>100 HP) DC motors that came with this equipment would need to be rebuilt or replaced. Before proceeding we presented our customer with a summary of the differences between AC and DC motors along with a cost analysis for both. The customer in this case liked the benefits that came from AC motors and drives, so we tailored our design to their request. We utilized the existing control panels that were purchased in the sale to house new subplates that were built by our local panel shop using existing and new components. Finally, we were able to utilize many of the existing field devices, but some supplementary devices were recommended for purchase to aid with the overall stability of the line’s process.

Value

Providing the best solutions for our clients sometimes means taking the path less traveled. It is easy to recommend a new controls system for every project, but many times replacing everything is just not required. In the case above we were able to provide our customer with the data to make informed decisions about whether to replace key components of the equipment or not. This allowed the customer to pick the path forward with the most perceived value to them. This method allowed our customer to bring this process line back to life with a state-of-the-art controls system without breaking the bank.